SUBMERSIBLE electric motors, SUBSEA electric motors, ROV electric motors, ROV motors,

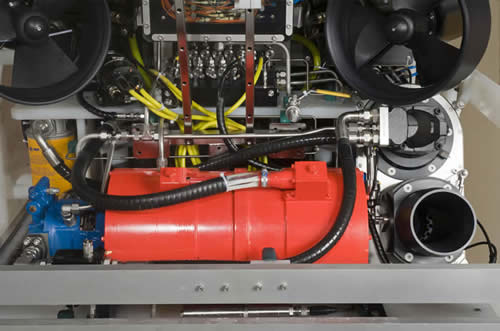

HPU's, ROV HPU's. SME electric motors. Subsea Pumps.

For SUBSEA vehicles, SUBSEA submersibles, SUBSEA trenchers, and SUBSEA equipment.

Submersible electric motors for sump pumps, and any special purpose submersible electric motor requirements.

SUBSEA + ROV ELECTRIC MOTOR REPAIRS AND REWINDS.

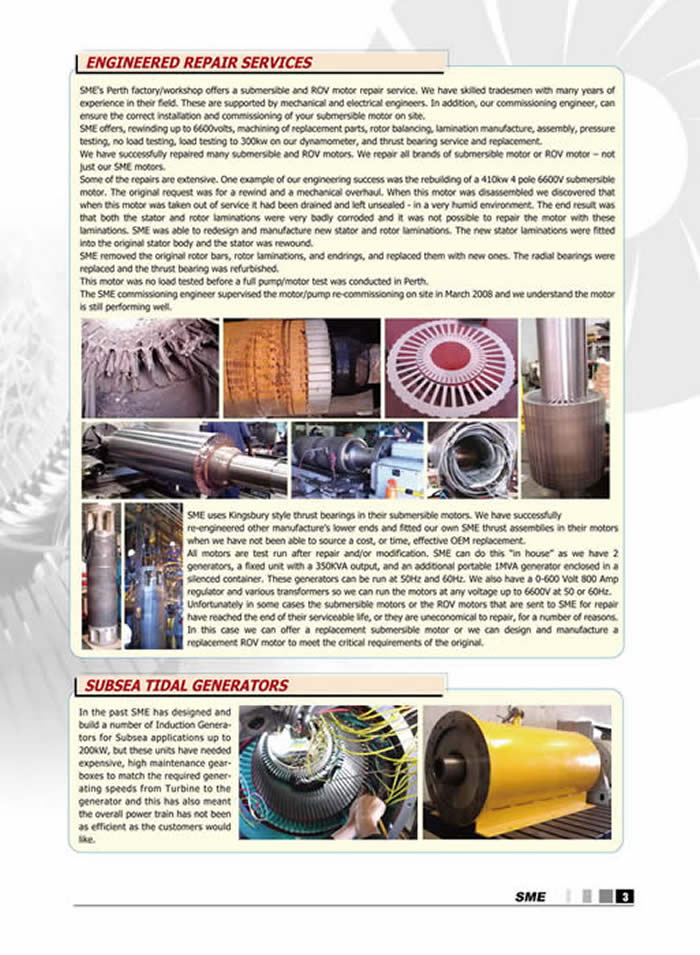

SUBSEA electric generators for Tidal Power Generation.

Silvercrest / Submersible Motor Engineering

Design, manufacture, and supply, submersible and ROV electric motors for all underwater applications.

Silvercrest / Submersible Motor Engineering

Can design and manufacture SUBMERSIBLE, SUBSEA, and ROV Motors to suit any requirement. We have manufacturing, submersible motor repair and service centers in Australia, the USA, and Great Britain.

We are totally flexible in our design capabilities: |

| |

| |

| |

| |

NEWS FLASH. SME and PLEUGER create Global Service Network for submersible motors. SME is pleased to announce the signing of a Memorandum of Understanding with Pleuger Industries to combine forces for the “After Sales Service” for submersible motors. The agreement provides SME access to Pleugers’ spare parts to assist in the overhaul and service of Pleuger products through the SME Service Network globally. The combined strengths of Pleuger Industries and SME will ensure that we are able to supply a World Class Service network to all existing and future clients. SME will purchase and resell original Pleuger spare parts for submersible electric motors. SME designs and manufactures submersible and underwater electric motors for complex bespoke applications. SME offers repair, rewind, modification and technical support services in Australia, Great Britain, and the USA for its own SME product range. Also, for the products of all other subsea or submersible motor manufacturers. For more information contact: sales@Silvercrestsubmarines.com

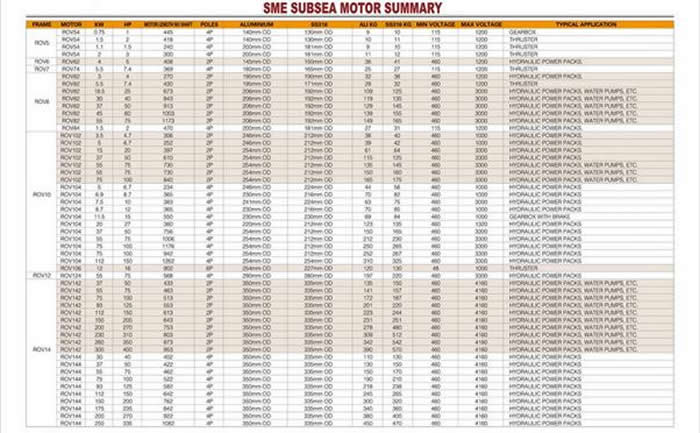

Subsea Electric Motors & ROV Electric Motors. SME design and manufacture a world leading range of Subsea Electric Motors, including motors for HPU’s on ROV‘s, Electric Thrusters for Manned Submarines, and Heavy Duty Jetting Pumps on Subsea Trenchers. SME motors are robust and reliable in the toughest of environments. Our flexible design capabilities mean we can manufacture Subsea Motors to suit any application. Our range of motors allow Flexible External Dimensions to suit all requirements and provide the possibility of “Drop In‘’ replacement motors. SME have produced over l00 different types of Subsea motors and thousands of motors. We offer a variety of Construction Materials from Anodised Aluminium to Exotic Stainless Steel Alloys to ensure long term reliability in varied environments whilst still offering the advantages of light weight design. To ensure the integrity of the motors SME does not use castings and all components are manufactured from solid metal or extrusions. Motors can be offered with a variety of Interfaces for Driven Equipment — from Robust Shafts with Multiple Shaft Seals to Close Coupled Motors with Female Spline Hubs to allow direct fitment of Hydraulic Pumps. SME can design and manufacture from the “Lamination Up” to ensure the Motor is ideally suited for the application. This bespoke Manufacturing policy ensures we can meet any special design requirements. SME can build motors from Fractional Kilowatt Motors right through to large outputs in the Megawatts and above to ensure we meet all requirements. SME Subsea Motors can be manufactured in all voltages from 240Vac through to 6600V at 50Hz or 60Hz, or for use with Variable Speed Drives. Due to SME’s proprietary Insulation System motors up to 4l60V can be built with a Random Winding to reduce size and weight whilst losing nothing in terms of reliability. This insulation system is specifically engineered to ensure suitability of operation in Hydraulic Oil or many of the Bio-Degradable Oils commonly used for Compensation circuits. All motors are designed for external compensation allowing for operation at depths as much as 4000M. The Motors can also be offered with Cooling circuits to ensure high output motors maintain minimal operating temperatures at Full Load. SME Motors are fitted with Water Detection Probes and Temperature Detectors and these can be terminated to a variety of different Subsea Connectors. Power can be supplied to the motors through Subsea Connectors or Highly reliable Oily Tube Connections. SME’s extensive testing facilities ensure we can test these Subsea Motors at rated Voltage and Frequency. This testing can also involve Hydraulic Load testing on a HPU or Flow and Pressure Testing of Jetting Pumps in our Test tank. Full string testing involving the Drives, Control Gear, Motor and Driven equipment can also be organised. Submersible Motor Engineering’s extensive Service Capability also ensures we are the best location for Service and Refurbishment of Subsea Motors of any manufacturer. Quite often SME can return motors to their clients in a better than new condition due to our ability to implement the latest Engineering Practices into the repair process.

|

SUBSEA/ROV MOTORS. Silvercrest/SME specialize in the bespoke manufacturing of submersible motors, HPU's, and pumps for use on ROVs, subsea trenchers, subsea ploughs, dredgers and water lift pump systems, for use in the offshore Oil and Gas and Telecommunications industries. We offer a range of submersible motors (5hp to 1500hp) with a choice of voltages (ranging from 380vac to 6600vac) for use subsea to depths of 6000msw. All of these motors are available in either SS316, Duplex, Super Duplex, or Hard Anodized Aluminium finish. We can also design and build motors to suit your individual and special project requirements. In addition we refurbish, rewire, and service a wide range of submersible motors. Our product is excellent, our prices very competitive, and our delivery schedule the best in the industry. We recently delivered ten 260kW, 3000VAC, double ended, 2-pole, stainless steel bodied motors to a subsea operator, for use on their fleet of sub-sea trenchers. This was a bespoke order that was completed in just six weeks from receipt of order. In addition we also recently manufactured five (5) 400kw motors for SMD. We have supplied submersible motors, HPUs, and motor-pump sets to SMD, Fugro, Impresub, Saab SeaEye, LDtravocean, Geocean, ASME, AssoDivers, Blade Offshore, CT Offshore, D&R Subsea, DCNS, Deep Ocean, ERA Ltd, Fearsome Engine, Film Ocean, JVPC, MaCorp, ISE, NIOT, Sonsub, Subsea 7, IHC, Total Marine Technology, ETA, Oceaneering, Shell, Petronas, Murphy Oil, Haechun, Canyon, Caldive, Exxon, Ocean Force Management, Osbit Power , OTN, Perry, PFS, Saab SeaEye, STS ROV, Weir Group, Hibbard, Simec, Sulzer, WeSubsea, OESEF, Hydrobotics, UTROV and other subsea companies worldwide. We will be very pleased to discuss the details of your future subsea motor / pump requirements in order to produce a detailed quotation for you. Email: sales@Silvercrestsubmarines.com

We design, manufacture, and supply, submersible electric motors for all SUBSEA and ROV, SUBSEA equipment, also for any special purpose submersible electric motor requirements. We manufacture and repair ROV submersible motors for all subsea application. We repair and rewind large high voltage (500kW, 6600V) submersible electric motors.

We offer a wide range of electric submersible motors with matched hydraulic and water pumps. We have our own submersible motors that are drop-in replacements for most of the popular models in use. We manufacture complete submersible electric motors, motor-pump sets, and ROV HPU. SME has years of experience with the design and manufacture of submersible motors, used in the offshore, subsea, military and dredging industries. This experience has resulted in SME being the company of choice as a manufacturer and supplier for many of the major offshore subsea companies. SME submersible motors are specially designed to suit our customer requirements. With special attention being paid to the motor design. Resulting in SME manufacturing rugged motors with low maintenance requirements, a very high reliability, and a long service lifetime.We offer submersible motor rewind / rebuild /electrical conversion / and original construction modification. We supply ROV HPU submersible motors from 30kW to 250kw, trenching HPU submersible motors from 100kW to 500kW, trenching jetting pumps, plough HPU submersible motors, plough jetting pump sets, turbine and centrifugal water pumps, and hydraulic pumps (Rexroth A7 and A10 series, Sauer 90 series and Kawasaki KV3 series).

|

|

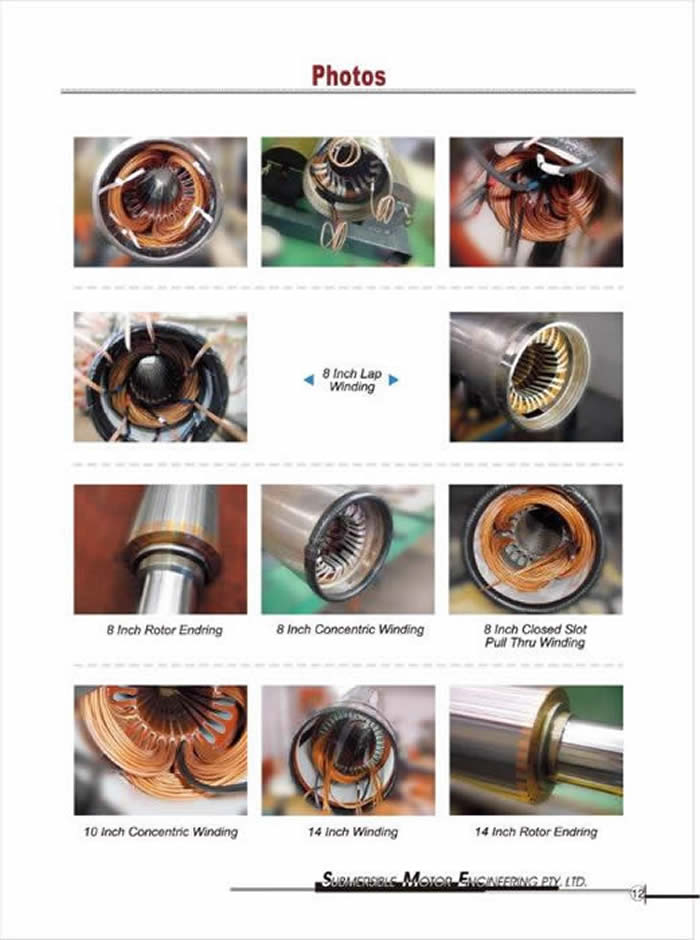

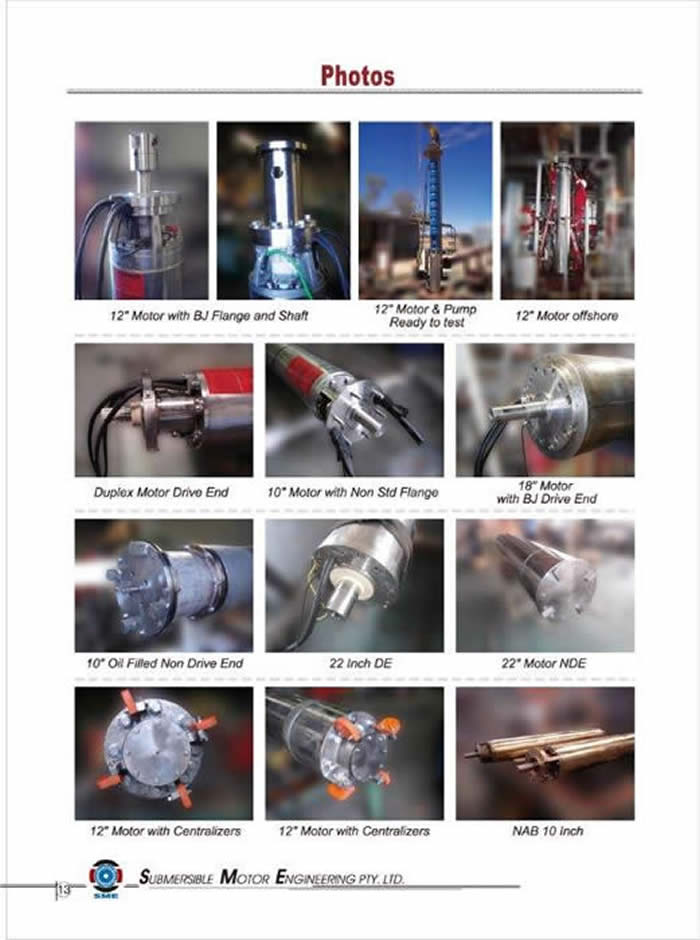

All the photos above show motors designed and manufactured by Silvercrest / Submersible Motor Engineering. ROVs, Trenchers, and Submarines, shown in the photos are fitted with Silvercrest / Submersible Motor Engineering electric motors.

SILVERCREST / SME. Tel: (+44) 1285.760620. Email: sales@SilvercrestSubmarines.com

SUBMERSIBLE MOTORS, ROV MOTORS, SUBSEA MOTORS for Sale. MOTOR-PUMP SETS, ROV HPU for Sale. TIDAL ELECTRIC GENERATORS.

Silvercrest / Submersible Motor Engineering specialize in the bespoke manufacturing of submersible motors, Rov motors, and subsea motors, motor-pump sets, and HPU's for use on Rovs, subsea trenchers, subsea ploughs, dredgers and water lift pump systems. For use in the offshore Oil and Gas and Telecommunications industries, and subsea to depths of 4000m. We offer a range of motors, motor-pump sets, ROV HPU, submersible, subsea and Rov motors (5hp to 1500hp) for use in the more popular classes of subsea ploughs and Rovs. All of these motors are available in either SS316, Duplex, Super Duplex stainless steel, or with a hard anodized aluminium finish. We can offer subsea submersible motors with a wide range of speeds and voltages (including 3000v, 6000v and 10,000v). Silvercrest / Submersible Motor Engineering will design and build motors to suit your individual and special project requirements. We refurbish and service a wide range of submersible motors. Our product is excellent, our prices very competitive, and our delivery schedule the best in the industry.

Submersible Motor Engineering/Silvercrest is the world leader in submersible motor technology, enabling our customers to explore deeper underwater than ever before. High power, high voltage and high-pressure specifications are common place for many of our clients. Our submersible subsea and ROV motors are the best on the market today, offering a comprehensive choice of materials and design to underwater and ROV operators. Submersible Motor Engineering/Silvercrest specializes in all aspects of submersible electric motor operation, performance, and design. Due to industry demand for readily available quality parts, we also rewind, repair, redesign, and machine major components of other manufacturer's motors that require repair and re-manufacture.

CONTACT US TODAY TO DISCUSS YOUR SUBSEA MOTOR REQUIREMENTS. Email: sales@SilvercrestSubmarines.com Email: sales@SilvercrestSubmarines.co.uk

SME(UK) has now opened our new submersible motor service facility in the United Kingdom.

SME(UK) now offer a complete submersible electric motor repair facility for: Rewinds / rebuilding /electrical conversion / construction modification. We also design and build specialized motors for use SUBSEA for the offshore industry. Installation and start-up technical support. Have a problem and need help with your subsea motor, then we offer the best choice in consulting services. Troubleshooting. Any type of mechanical repair. Shaft. Bearings. End bells. Seals. Testing. Repair and rewind of large high voltage (500kW 6600V) submersible electric motors. SME High Temperature Submersibles in 6"to 20" frames suitable for operation in ambients of 75 Deg.C High Voltage water filled submersible motors-3300V,4160V and 6600V. Upgraded Temperature Monitoring unit available with new improved user friendly parameter setting. SME ROV and Subsea motors suitable for depths of 4000m. ROV HPUs. Subsea Motor-pump sets. Subsea Electric Generators for Tidal Generation. Induction Generators or slow speed Permanent Magnet Synchronous Generators up to 500kW. SME (UK) designs, manufactures and supplies water filled and oil filled ROV and subsea submersible motors globally. SME (UK) is a full Sales, Service & Repair division for the factory in Australia. SME (UK) offers repair of all submersible electric motors. SME (UK) can rewind and completely rebuild the following listed motors. Alstra, Aturia, Bamsa, B. J., Elmaksan, Exodyne/EEMI, G.E., Hayward Tyler, Hitachi, Mercury, Oddesse, Pleuger, Saer, S.M.E., Subteck, Sumo, Sun Star, U.S.

SME WATER JETTING PUMP for ROV TRENCHERS. Silvercrest/SME now offers high quality, robust and reliable, water jetting pumps complete with SME submersible motor for all subsea operations. Ideal for ROVs, subsea Trenchers, Dredgers and other underwater applications. Silvercrest/SME supply our own Pump/Motor combination. We offer a 2- pole, or 4-pole motor, coupled to our own designed pump (especially designed for trenching applications). Depth rating is 3000msw plus. The pump and motor combination is rigorously tested in our factory to full performance before despatch.

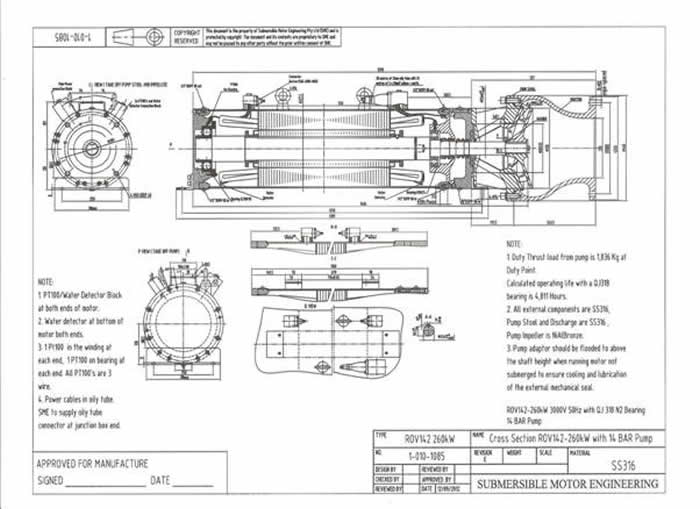

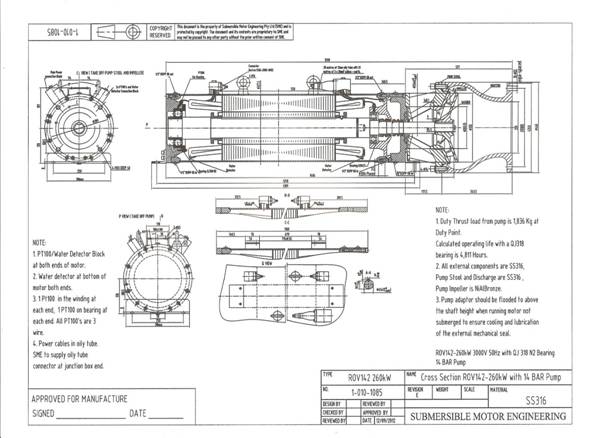

We recently delivered ten 260kW, 3000VAC, double ended, 2 pole, stainless steel bodied motors to CTC Marine Projects Ltd, for use on their fleet of sub-sea trenchers. This was a bespoke order that was completed in just six weeks from receipt of order. Also five 400kw, 4 –Pole, 3300/3/60, SS316 Construction, Subsea Submersible Motors for SMD. Silvercrest / Submersible Motor Engineering supply submersible motors, HPU's, and motor-pump sets worldwide. Our customers include SMD, Saab SeaEye, Ldtravocean, Fugro, CTC Marine Projects, Perry Slingsby and many others.

Subsea Trencher fitted with our SME 142-265KW stainless steel construction submersible motor and pump.

Silvercrest / Submersible Motor Engineering have manufactured and recently supplied six 400kw ROV20-4 motors, 4-pole/3300vac/3 phase/60hz, stainless steel construction. Single ended for fitment with Sauer hydraulic pumps Series-90-L250. Rated for 3000m depth operations. Also three ROV204 submersible motors (300kw/4 pole/3300vac/3 phase/60hz) with stainless steel construction, and double ended for fitment with Sauer hydraulic pumps to SMD-Hydrovision. Together with 7.5kw motors for Rov cursor application. Silvercrest / Submersible Motor Engineering has manufactured a seven (7) 6600V motors, for three different offshore contracts. Petronas Dulang and Angsi Platforms. Star Energy KG Platform.

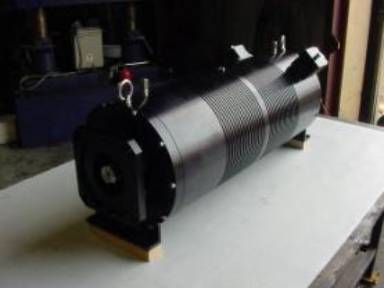

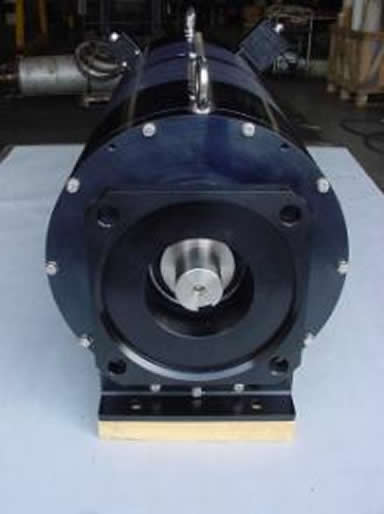

A new Saab-SeaEye Jaguar ROV, fitted with our SME ROV12-2, 48kW 65HP, 2-pole, 3000/3/50, aluminium construction ROV submersible motor, and Rexroth hydraulic pump. Fitted with temperature sensing and water detectors. Epoxy coated for protection.

SME motor with Heat Exchanger.

Two submersible double-ended motors mounted with hydraulic pumps, fitted to a submarine digger. SME ROV14-4, 75kW/100HP, 4–pole, 3000/3/60, Anodised Aluminium Subsea Motors with Interface to suit the Hydraulic Pumps.

SME 260Kw submersible motor-pump set fitted to a subsea trencher.

Silvercrest / Submersible Motor Engineering is a leading manufacturer of high quality submersible motors and pumps, designed specifically for subsea operations.

SME ROV 65Hp MOTOR with Fybroc Centrifugal Water pump.

SME manufacture and design subsea electric motors, either water or oil-filled for all ROV and subsea applications. SME design, manufacture, and supply, submersible electric motors for bore holes, SUBSEA and ROV electric motors for SUBSEA equipment, submersible electric motors for sump pumps, and any special purpose submersible electric motor requirements. SME also offer SUBSEA electric generators for Tidal Power Generation.

Submersible Motor Engineering design, manufacture, and supply, submersible electric motors, SUBSEA and ROV electric motors for all SUBSEA equipment, ROV HPUs, submersible electric motors for sump pumps, and any special purpose submersible electric motor requirements. Submersible Motor Engineering also offer SUBSEA electric generators for Tidal Power Generation.

269kw motors fitted with pumps and heat exchangers.

SME Repair and Rewind large high voltage (500kW, 6600V) submersible electric motors.

We manufacture and rebuild very large submersible motors for a range of different offshore and subsea companies. These include: Global Marine, CTC, Sonsub, Star Energy, Sulzer Wood, Sulzer, Fugro, Apache, BHP Billiton, Petronas, SMD, Exxon Mobile, Chevron, Perry Slingsby, Subsea7, Bayu Purnama, ISE Ltd, Saudi Aramco, Woodside, PXP.

SME 150kw Water Jetting Motor-Pump set. SME 195Kw subsea motor.

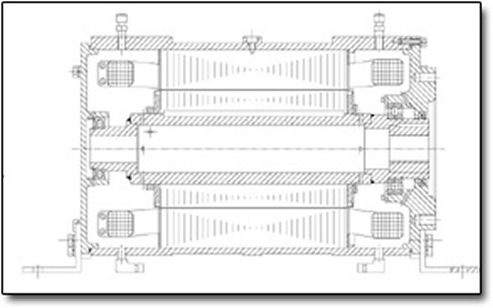

260kW Silvercrest / Submersible Motor Engineering Pump Motor under construction.

Submersible 15Kw ROV HPU. Subsea Submersible Electric Motor.

Silvercrest / Submersible Motor Engineering will bespoke manufacture virtually any shape and size of submersible motor required for subsea operations. We will be very happy to discuss the details of your subsea motor / pump requirements in order to produce a detailed technical quote for you.

Silvercrest / Submersible Motor Engineering design and build specialized subsea motors, and support packages for use on all types of Rovs and underwater vehicles in the offshore and subsea industry. These submersible motors are usually made to order and vary from 1kW to 1500kW, 400 to 6600 Volts. 50 or 60 Hz, 2-Pole to 8-Pole. There are two common methods of construction available: - Stainless steel construction, or Marine Grade aluminium that is Black anodised to resist corrosion. In addition we can offer Duplex and Super Duplex stainless steel construction. These motors are usually oil filled and pressure compensated. Common operating voltages are between 300 volts and 3300 volts - even for small 5kW motors. 6,000vac and 11,000vac motors also available by special request. Certain subsea motors can operate down to depths of 10,000 meters.

Silvercrest / Submersible Motor Engineering manufactures new Submersible, Subsea, and Rov motors. Silvercrest / Submersible Motor Engineering rewinds, services and repairs all brands of Subsea, Submersible and Rov motors. Including Hitachi, Pleuger, Grundfos, Mercury, Byron Jackson, Haywood Tyler, and Franklin. Silvercrest / Submersible Motor Engineering is a leading manufacturer of high quality submersible motors and pumps, designed specifically for subsea operations. Silvercrest / Submersible Motor Engineering specialize in the bespoke manufacturing of submersible motors, pumps and ancillary equipment for use on Rovs, subsea trenchers, subsea ploughs, dredgers and water lift pump systems, for use in the offshore Oil and Gas and Telecommunications industries.

75HP Rov Subsea Motor.

We manufacture our own laminations, designed specifically to meet the individual requirements of each customer. We do not buy off the shelf standard rotor sets and fit them in a housing, as some other manufacturers will often do. As a result our motors are more efficient and generally ightly smaller, in both diameter and length, than our nearest competitors for any given power rating. Silvercrest / Submersible Motor Engineering offer a range of ‘standard’ motors for use in well-established underwater installations, such as the more popular classes of Rov and subsea ploughs.

Silvercrest / Submersible Motor Engineering offer: Repair and rewind of large high voltage (500kW, 6600V) submersible electric subsea motors. High Temperature Submersible subsea motors in 6-inch to 20-inch frames suitable for operation in ambient temperatures of 75 Degrees C. High Voltage water filled submersible subsea motors (3300V, 4160V and 6600V). Upgraded Temperature Monitoring units available with new improved user-friendly parameter setting. ROV and subsea submersible motors suitable for depths of 4000m (10,000m depths by request). WD Series sump-pump motors. Subsea Electric Generators for Tidal Generation. Induction Generators or slow speed Permanent Magnet Synchronous Generators up to 500k.

CONTACT US TODAY TO DISCUSS YOUR SUBMERSIBLE MOTOR, SUBSEA MOTOR and ROV MOTOR REQUIREMENTS.

Tel: (+44) 1285.760620 Email: sales@SilvercrestSubmarines.com

Silvercrest / SME. “Excellence” in the manufacture of “quality” Subsea Electric Motors. We offer Subsea Electric Motors. Full Range of Speed Options. All Voltages and Frequencies. All Construction Options from Anodised Aluminium to Exotic Metal Alloys. Extensive Electrical and Hydraulic Testing Facility. Engineered Motor Solutions for Complex Applications . World Leaders in the Design, Manufacture, and Supply of Subsea electric motors. Over 2000 motors delivered and operating worldwide.

Contact us today: Email. sales@silvercrestsubmarines.co.uk

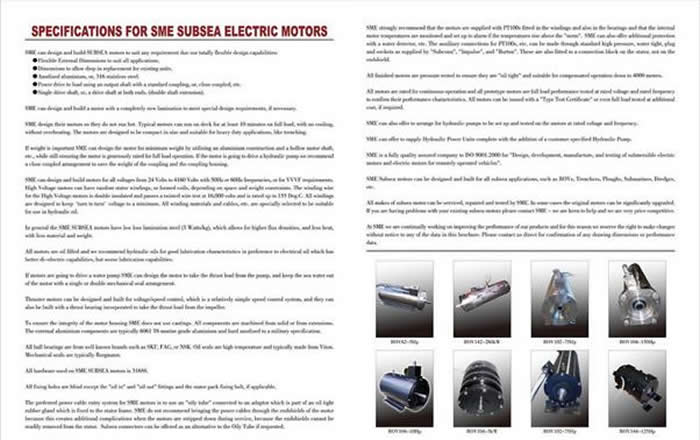

SME products have been designed and developed utilising many years of operating and service experience with submersible motors and subsea motors. SME are a quality assured company and are certified to ISO 9001 by SGS for “Design, development, manufacture and testing of submersible subsea electric motors”. SME produce their motors under a rigorous QA procedure to ensure that all motors are supplied in a “Quality and Reliability Assured” condition. In addition to ensuring the motors are supplied in excellent condition, SME believe it is their responsibility to try to ensure that the end users get many years of reliable life from their SME motors.

At SME we try to help the end user – not just sell them a motor in a box. We offer the services of experienced commissioning engineers to go to site and ensure the motors are installed, commissioned, and protected correctly. We also offer full 24 hour service and testing facilities. At SME we are continually working to improve the performance of our products and for this reason we reserve the right to make changes without notice to any of the data in this brochure. Please contact us direct for confirmation of any drawings dimensions or performance data.

SME SUBSEA MOTORS SME can design and build Subsea motors to suit any requirements, due to our totally flexible design capabilities: Flexible External Dimensions to suit all applications. Dimensions to allow drop in replacement of existing units. Anodised aluminium, or, 316 stainless steel or more exotic materials, such as Duplex. Power drive to load using an output shaft with a standard coupling, or, close coupled. Single drive shaft, or, a drive shaft at both ends, double shaft extension. SME can design and build a motor with a completely new lamination to meet special design requirements, if necessary. SME design their motors so they do not run hot. Typical motors can run on deck for at least ten minutes on full load, with no cooling, without overheating. The motors are designed to be compact in size and suitable for heavy-duty applications, like trenching.

If weight is important, SME can design the motor for minimum weight by utilising an aluminium construction and a hollow motor shaft, while still ensuring the motor is generously rated for full load operations. If the motor is going to drive a hydraulic pump we recommend a close-coupled arrangement to save the weight of the coupling and the coupling housing. SME can design and build motors for all voltages from 24 volts to 6600V with 50Hz or 60Hz frequencies, or for VVF requirements. High Voltage motors can have random wound stator windings, or formed coils, depending on space and weight constraints. The winding wire for the High Voltage motors is double insulated and passes a twisted wire test at 16,000 volts and is rated up to 155 Deg.C. All windings are designed to keep ‘turn to turn’ voltage to a minimum. All winding materials and cables are specially selected to be suitable for use in hydraulic oils. In general, SME Subsea motors have low loss lamination steel (3 watts/kg), which allows for higher flux densities, and less heat, with less materials and weight. All motors are oil filled and we recommend hydraulic oils for good lubrication characteristics in preference to electrical oil ( which has better di-electric capabilities, but worse lubrication capabilities). If motors are going to drive a water pump, SME can design the motor to take the thrust load from the pump and keep the sea water out of the motor with a single or double mechanical seal arrangement. Small thruster motors can be designed and built for voltage/speed control, which is a relatively simple speed control system and can be built with a thrust bearing incorporated to take the thrust load from the impeller.

To ensure the integrity of the motor housing, SME does not use castings. All components are machined from solid or from extrusions. The external aluminium components are typically 6061 T6 marine grade aluminium and hard anodized to a military specification.

All ball bearings are from well known brands such as SKF, FAG, or NSK. Oil seals are high temperature and typically made from Viton. Mechanical seals are typically Burgmann. All hardware used on SME Subsea motors is 316SS. All fixing holes are blind. Oil in and out fittings and the stator pack-fixing bolt, if applicable are sealed with O rings.

The preferred power cable entry system for SME motors is to use an “oily tube” connected to an adaptor, which is part of an oil tight rubber gland that is fixed to the stator frame. SME do not recommend bringing the power cables through the end-shields of the motor as this creates additional complications when the motors are stripped down during service (because the end-shields cannot be readily removed from the stator). Subsea connectors can be offered as an alternative to the Oily Tube if requested.

SME strongly recommend that the motors are fitted with PT100s fitted in the windings and also to the bearings. The internal motor temperatures are monitored and set up to alarm if the temperatures rise above a safe temperature. SME can also offer additional protection with a water detector. The auxiliary connections for PT100s, can be made through standard high pressure, water tight, plug and sockets as, supplied by “Subconn”, “Impulse”, and “Burton”. These are also fitted to a connection block on the stator, not on the end shield. All finished motors are pressure tested to ensure they are “oil tight” and suitable for compensated operation down to 4000 metres. All motors are rated for continuous operation and all prototype motors are full load performance tested at rated voltage and rated frequency to confirm their performance characteristics. All motors can be issued with a “Type Test Certificate” or even full load tested at additional cost, if required.

SME can offer to arrange for hydraulic pumps to be set up and tested on the motors at rated voltage and frequency. SME can offer to supply Hydraulic Power Units, “complete”, with the addition of customer specified Hydraulic Pump. SME Subsea motors can be designed and built for all subsea applications, such as ROVs, Trenchers, Ploughs, Submarines and Dredges. All brands of Subsea motor can be serviced, repaired and tested by SME. In some cases the original motors can be significantly upgraded. If you are having problems with your existing Subsea motor please contact SME – we are ready and able to provide assistance and we are very price competitive.

APPLICATIONS Driven equipment can include: Hydraulic Pumps: For ROV Hydraulic Power Units, Subsea Robotics, Thrusters, etc. Water Pumps: For Jetting Systems, Hull Cleaning, Trenching and Pipe and Cable Laying Equipment, Pipe Pressurisation, Dredging, etc. Propellers/Impellers: For Remotely Operated Vehicle Thrusters, Manned Submarine Thrusters, Mass Flow Excavation, etc. Gearboxes: For Subsea Winches, Cable Tensioners and De-reelers. Fish Pumps.

MATERIALS OF CONSTRUCTION SME can manufacture Subsea Motors in Aluminium (Grade 6061 T6), Stainless Steel(Grade 316), Duplex (SAF2205), Super Duplex (SAF2507) and other more exotic materials.

VOLTAGES Motors are available in AC Voltages from 24V to 6600V. Motors up to 4160V in Random Wound Designs. Above 4160V motors are manufactured using a Formed Coil system. Special random wound design motors may be available above 4160V for specific applications.

DEPTH RATING All SME's Subsea Electric Motors are designed for external compensation and have been used at depths of more than 4000M. Compensation advice can be provided on request.

SPEED Motors are available in a variety of speeds at both 50Hz and 60Hz. Synchronous speed at different numbers of poles. (Hz) 2P 4P 6P 8P 10P 12P 50 3000 1500 1000 750 600 500 60 3600 1800 1200 900 720` 600 Lower speed ratings are available on application. Motors are suitable for operation Using variable speed drives and SME can provide advice on variable speed drive operation if requested.

INSTRUMENTATION SME Subsea Motors are available with a range of instrumentation: Bearing and Winding Temperature Monitoring Water Ingress Detection Pressure Transducer Resolvers and Encoders Tachometers

COOLING Motors are generally designed to operate with no additional cooling other than the ambient water temperatures but in some cases external cooling may be required. SME can provide motors with closed loop cooling circuits or motors that are suitable for use with externally fed cooling circuits.

ELECTRICAL CONNECTIONS SME Subsea Motors use an oily tube termination for all power connections as standard. However, appropriately sized and rated Subsea connectors can be used as an alternative, either a Bulkhead Connection on the motor, or as part of a fixed Flying Lead Termination. Instrumentation is generally terminated using a variety of Subsea Connectors. Customers are free to specify their Connectors of choice.

MECHANICAL INTERFACE Motors are design built to suit the application and SME can supply a broad range of interfaces from direct coupled arrangements to the use of separate coupling housings. SHAFTS: Female and Male Spline Shafts, Internal and External Keyed Shafts. FLANGES: NEMA, IEC, SAE, DIN Standards are all available as well as unique requirements. Motors can be provided with Double Ended Arrangements to drive multiple loads.

MOTOR MOUNTING Motors can be provided with various Mounting arrangements including Feet, Flanges, Brackets, or Clamping. In most cases SME can match the mounting interfaces of units being replaced to ensure ease of installation in existing equipment. Motors can be manufactured for Horizontal or Shaft Up or Down installation.

COMPENSATION REQUIREMENTS Motors are built to utilise external compensation. Motors are fitted with oil in and out ports as well as several bleed points to facilitate easy plumbing. Fittings can be provided with BSP, NPT or JIC and other fittings with both straight and tapered threads to provided uniformity on the installation. There are a vast range of acceptable compensation fluids and SME can provide advice in the suitability of various oils.

SME MOTOR RANGE SME is able to provide many and varied Subsea Motors to suit specific applications. Please contact us to discuss your requirements.

SUBSEA PUMPS SME design and manufacture a world leading range of Electric and Hydraulically Driven Subsea Pumps. These are designed to operate as Heavy Duty Jetting Pumps on Subsea Trenchers and Ploughs, Subsea Dredging and Excavation Equipment. SME Pumps are robust and reliable in the toughest environments. Our flexible design capabilities mean we can manufacture Subsea Pumps to suit most applications. We offer a variety of Construction Materials from 316 grade Stainless Steel to Exotic Stainless Steel Alloys, with nickel aluminium bronze impellers. SME Electrically Driven Subsea Pumps can be manufactured in all voltages from 380V through to 6600V at 50Hz or 60Hz, or for use with Variable Speed Drives. All pump motors are designed for external compensation allowing for operation at depths as much as 4000M. The Motors can also be offered with Cooling circuits to ensure high output motors maintain minimal operating temperatures at Full Load.

TESTING SME‘s West Australian facility, located in Perth, provides for an extensive testing regime for repaired and overhauled motors. SME can full load test motors on our dynamometers and can also offer performance testing of complete pump/motor units in our purpose built test tank – at the specified voltage and frequency up to 6600 volts. SME can guarantee motors that have been serviced and repaired are fit for purpose before dispatch, providing customers with complete confidence in the work prior to re-installation. All motors that re rewound by SME are subject to an immersion pressure test which is conducted in our pressure test vessel to ensure the integrity of the windings prior to assembly and load testing. Our commitment to a strict testing regime protects our clients from the risks of downtime caused by unexpected failure. Our Factory offers the following equipment: High Voltage Transformers 1000/2400/3300/4160/6600V High Current Voltage Regulator Dynamometer Load Test Equipment 300kW/2600kW Power Generation 350kVA/1350kVA 15kV Hi Pot and Surge Tester Subsea Pump Testing Facilities

SME COMPANY PROFILE Submersible Motor Engineering Pty Ltd is an Australian Company that designs and manufactures Submersible and Subsea Electric Motors for Global Markets. SME has the ability to design and produce specialist electric motors for complex applications, in many cases for a “one off” requirement. SME should be the company of choice to work with to provide High Quality Engineered Solutions for your Subsea Motor requirements. SME offers a Repair, Rewind Modification, and Technical Support Service, in Perth, and in Phoenix. With a new facility soon to be opened in the United kingdom. Our facilities ensure that we can handle any job we are confronted with, regardless of complexity. Our purpose built testing facility ensures absolute confidence in workmanship and reliability for our clients. When it comes to Sales and Service of Submersible and Subsea Motors, SME’s range of Worldwide Locations ensures that we can provide excellent service and technical support on our own SME range of products, but also the products from all other manufacturers of Subsea Motors.

SUBMERSIBLE MOTOR-PUMP SET (HPU) for IMMEDIATE SALE.

New 65Hp submersible Rov HPU for sale. The motor-pump set is brand new, direct from our factory and has been constructed specifically for this purpose.

SME ROV12-2, 48kW 65HP, 2-pole, 3000/3/50, Aluminium Construction ROV Motor fitted with Rexroth A10VO28DFR1/31R-PSC62N00 Hydraulic Pump. Burton Connector for Power Leads. Fitted with Temperature Sensing and Water Detectors.

Mil Spec hard-anodised T6 hardened 6061 grade Aluminium construction, with all 316 hardware. Rotor dynamically balanced. Oil filled externally compensated. Fully factory performance tested on Dynamometer at rated voltage and frequency. Subsea connectors for power and instrumentation. Designed for maximum electrical efficiencies to reduce full load currents. Motor designed for low operating temperatures to extend reliable lifespan. Specialised winding insulation system to ensure long operating life, even under the most arduous of duties. On Deck operation generally allowable. Location. UK.

SILVERCREST/ SME Tel: (+44) 1285 760620 Email: sales@SilvercrestSubmarines.com

Submersible Motor Engineering manufacture: High temperature submersible subsea motors for 55 deg.C. water ambient. High efficiency water filled submersible subsea motors. All stainless steel construction submersible subsea and ROV motors. Full performance testing of submersible motors. 1000V and other special voltages - NO PROBLEM! Super Duplex submersible subsea motors. We offer a wide range of electric submersible motors, with matched hydraulic and water pumps for use subsea, and with underwater vehicles, and ROVs. Drop in replacement motors for most of the popular submersible motors in use offshore and subsea. Subsea ROV Trenching Motors, Hydraulic Pumps and Water Pumps. We supply ROV HPU submersible motors from 30kW to 150kW. Trenching HPU submersible motors from 100kW to 500kW. Subsea trenching jetting pumps, subsea plough HPU submersible motors, subsea plough jetting pump sets, turbine and centrifugal water pumps, and hydraulic pumps (including Rexroth, Sauer, and Kawasaki). HPU (Hydraulic Power Units) for subsea, and ROV operations. Submersible Motor Engineering Hydraulic Power Units (HPU) are used throughout the subsea oil and gas industry, for subsea hydraulic power generation, and for running high pressure/high flow water pumps.

200kw, 4160v, Submersible motors ready for shipping to a subsea operator.

ALSO AVAILABLE.

SME MOTOR-PUMP SET for ROV TRENCHERS. Silvercrest / Submersible Motor Engineering can supply our own Pump/Motor combination. We offer a 2- pole, or 4-pole motor coupled to our own designed pump (especially designed for trenching applications). Depth rating is 3000msw plu For example : SME ROV14-4, 185kW 250H, 4 Pole, 4160/3/60, SS316 Construction Subsea Motor. Fitted to SME SS316 Construction/NAB Impeller Water Pump to produce 390m3/hr at 16 Bar.

Down Hole Submersible Motor. s. The pump and motor combination is rigorously tested in our factory to full performance before despatch.

4- Pole Down Hole Motor for submersible pump application. 10hp/4 pole/ Low RPM motor. We are pleased to offer our: SME 10 inch, 10HP, 4 Pole, 400/3/50, SS316 Construction Submersible Motor. A submersible motor for use on a subsea pumping project.

SME WATER JETTING PUMP (NOW AVAILABLE). SME now offers a high quality, robust and reliable, water jetting pump complete with SME submersible motor for all subsea operations. Ideal for ROVs, Trenchers, Dredgers and other underwater applications. The SME Jetting Pump comes complete with a 265kW, 2- Pole, 3300V 60Hz, 3500rpm, all 316 Stainless Steel motor. The Pump is single stage with the impeller mounted directly onto the motor shaft (So no pump bearings to wear). This Impeller is easily removed and replaced as the only wear point. Easy on site serviceable. This pump provides flow rates from 1000-1500m3/h.

High voltage subseaTrencher motors for water jetting.

150 KW, 3000V, 60HZ, 2 Poles, 3500 RPM, Compensation: Oil Filled. Power Connector: Burton. Sensor Connector: Subconn. This motor will be coupled with a Pleuger water pump. We are pleased to offer our: SME ROV14-2, 200HP 150kW, 2 pole, 3000/3/60, SS316 Stainless Steel Construction Motor to suit operation with Water Jetting Pump.

250Kw Motors for new Underwater Vehicle.

New 250Kw motors for new build Underwater Vehicle, to be mounted with hydraulic pumps. Our ROV14, 250kW / 335Hp, 4-Pole, 1800rpm, 4000/3/60, Anodised Aluminium Construction Subsea Motor to Drive Hydraulic Pump. Interface to suit Hydraulic Pump.

High voltage motor-pump set to be used subsea at a depth of 6000msw.

The requirements being 3000VAC 50Hz, 15kW, 1500rpm (motor), 20 Lpm (hydraulic fluid flow rate), 21 Mpa (pump outlet pressure). We can offer the following motor-pump set complete. SME ROV10-4, 15kW 20HP, 4 Pole, 3000/3/50, Aluminium Construction Subsea Motor, Coupled to Rexroth A10VSO18DFR Hydraulic Pump to give 20L/m at 21 Mpa. Epoxy coated for protection.

Submersible electrical motor. Input voltage 380 Volts and 50 Hz. The application being for a hydraulic power pack aggregate which will work on a ship, and be in contact with sea water. Power capacity of the motor should be around 25 -30 kW and speed of rotation about 1400 - 2000rpm, pressure 500 bar. We can offer the following motor, SME ROV10-4, 30kW, 4 Pole, 1500rpm, 380/3/50, Aluminium Construction Subsea Motor to Drive Hydraulic Pump, Epoxy coated for protection.

Heat Exchanger Motors.

We now offer a complete range of water filled, watertight, submersible subsea motors with integral heat exchangers in 10-inch, 12-inch, 14-inch and 16-inch size for 2 pole and 4 pole speeds.

These subsea motors offer a significantly lower temperature rise when compared with standard submersible subsea motors. This is an advantage that can be utilized when customers want to operate in water with a high ambient temperature, or when there will be minimal cooling water flow available. Even with the standard applications the lower temperature rise will extend the life of the motor significantly. There is an accepted rule of thumb for electrical insulation that its life is shortened by one-half for every 10°C increase in operating temperature. The winding operating temperature for a normal water filled submersible motor is about 70 degrees.C, in 25 degree.C water. However an SME Heat Exchanger Motor will be running at about 45 degree.C. (This is 25 degrees cooler). This magnitude of difference in temperature rise will have a significant positive impact on motor life.

The basic design principle for these subsea motors is to circulate the internal water in the motor remove the heat from the "active" parts of the motor, and then pass it through a heat exchanger which brings the internal water back to somewhere close to the external ambient water temperature - before feeding it back through the "active" parts again to remove more heat. The heat exchanger increases the external surface area of the motor by 50% and the water circulation allows the heat to dissipate more evenly and quickly out of the subsea motor and into the external water. The small impeller inside the subsea motor that circulates the water has an insignificant impact on the motor efficiency in terms of additional load, while the subsea motor has an improved efficiency because the stator and rotor copper losses are reduced due to the lower operating temperature.

Motor Thermal Protection Unit

All SME Heat Exchanger Motors come with four (4) PT100 temperature sensors installed in the motor. One PT100 is attached to the thrust bearing assembly that will detect excessive thrust loads and overheating in the thrust bearing. One PT100 is installed in the end winding on the non-drive end of the motor. One is installed half way down the slot in the winding in the middle of the motor. One is installed in the end winding on the drive end of the motor.

SME can offer one temperature protection unit (SME4TM) to monitor all four PT100'S installed in the Heat Exchanger Motor.

Water Pump Motors. Our water pump motors are not vertically oriented, water filled, down hole pump motors, as has previously been the norm throughout the subsea industry. Silvercrest / Submersible Motor Engineering motors are substantial oil filled submersible motors, designed to run in the horizontal axis with a large thrust bearing assembly to withstand water pump loads. We can offer specially designed turbine pumps to match our motors. Again these pumps are not the usual vertically oriented type, these are specifically designed with a twin bearing arrangement, for use in the horizontal axis. Thus dramatically extending operational life and improving pump reliability. Silvercrest recently delivered ten 260kW, 3000VAC, double ended, 2 pole, stainless steel bodied motors to CTC Marine Projects Ltd. The motors will be used by CTC on their subsea plough and trenching vehicles worldwide. This was a bespoke order that was completed in six weeks from receipt of order, ex-works from our manufacturing facility in Australia. The 260kW/ 3000V / 60Hz / 2 pole pump motors (designed specifically for use in the horizontal axis) were fitted with shafts at both ends, in order to mate with three tandem mounted hydraulic pumps on one end and a Hayward Tyler M6 single stage water pump-set on the opposite end. In this 260kW model, rather than using the pivot shoe arrangement, typical of vertically oriented pump-sets, heavy duty tapered roller bearings were fitted to the rotor to manage the water pump induced end-loads. Thus giving a calculated bearing life in excess of 11,000 hours, even when used in the horizontal axis. Depth rating on each motor is 10,000 meters, with oil filled compensation. Motor housings are 316 stainless steel, with Mylar coated windings (the ultimate in winding coating technology) being used in each motor at the request of CTC, giving an insulation rating of >16kV at a temperature of 140 degrees C.

Rov and Subsea Plough and Trencher Motors. Silvercrest offer an established range of Rov motors ranging from 5HP to 500HP. All of these motors are available in either SS316 or Hard Anodized Aluminium finish. We will also design and build submersible motors to suit your individual requirements and subsea project. Our motors are in use with most of the major operators worldwide such as Saipem, SMD Hydrovision, Sonsub, CTC Marine Projects, Impresub, Fugro, Thales, MTQ, LD Travocean and Canyon Offshore.

100HP Aluminium Bodied ROV HPU Motor.

75HP Plough Motor 11.kW Submarine Thruster. 265KW Trencher Motor.

400Kw Motor/3000vac for Subsea Trencher.

Submersible ROV HPU and Compensation Units. Silvercrest / Submersible Motor Engineering manufacture and supply a wide range of electric submersible motors, motor-pump sets, together with matched hydraulic pumps (HPU) or water pumps. We can supply ROV HPU submersible motors from 30kW to 250kW, trenching HPU submersible motors from 100kW to 450kW, trenching jetting pumps, plough HPU submersible motors, plough jetting motor pump sets, turbine and centrifugal water pumps, hydraulic pumps, Rexroth A7 and A10 series pumps, and Sauer 90 series & Kawasaki KV3 series pumps. We also offer a range of subsea components for manned submersibles, ROVs, submarines, subsea trenchers and subsea ploughs. Also oil compensation units (Compensators). We supply AC thrusters as direct replacements to existing DC thrusters from 1kW to 50kW in size.

Oil Compensator Units. Silvercrest / Submersible Motor Engineering supply oil compensator units for subsea vehicles, to suit manned submersibles, ROVs, submarines, subsea trenchers and subsea ploughs, and subsea equipment. We can offer a range of oil compensation unit sizes, including a 2.7L Compensator. 7 x 1/4" NPT (BSPT). SA-HC-0745-MAS.

This is a rolling diaphragm, positive pressure compensator (2700cc capacity), manufactured in corrosion resistant plastic suitable for ROV and tooling applications. These units are particularly suitable for compensating thrusters, compensating oil filled junction boxes, compensating valve packs, and other subsea applications

Motor-pump sets (depth rated to 3000m) for subsea trenching operations. Silvercrest / Submersible Motor Engineering has recently manufactured and supplied two 265kw motor-pump sets for SMD-Hydrovision (England). The package comprised 265kw subsea motors, 2-pole, 3000v, 3ph, 60hz. Together with Jetting Pumps (wet end only, operating at 2-pole, 60 hertz). The motors were a stainless steel construction, and the pumps Zinc Free Bronze. These motor-pump sets will be installed onto one of the world’s largest subsea trenching vehicles. In addition, Silvercrest / Submersible Motor Engineering has manufactured and delivered in just eight weeks from order, two water turbine pumps to CTC Marine Projects based in Teeside (England). The pumps will be used by CTC, in conjunction with Silvercrest / Submersible Motor Engineering submersible 260Kw motors, on their subsea plough and trenching vehicles worldwide.

The two Silvercrest SH-M6R submersible pumps with a 231mm OD impeller and a nominal operating speed of 3600rpm will be used as an alternative to the Hayward Tyler model M6-1 stage CI/BR/SS submersible pump. The Silvercrest pump although matching the performance of the Hayward Tyler unit, is specifically designed for horizontal operation providing a greatly increased reliability for use in horizontal and downward angled operation.

Examples of Submersible motors we have manufactured.

SME 10-inch motor, 110kW 2P 400V 50Hz Super Duplex Construction for Service Water Lift Pumps.

SME 36-inch, 550kW -540HP, 4 Pole, 10000/3/50, Super Duplex Construction Submersible Motor.

SME 12-inch 150kW 200HP 4 Pole 480/3/60 Super Duplex Construction Submersible Motor c/w 60M of Submersible Cable.

SME 36-inch 2200kW 6-Pole 6600/3/60Hz Super Duplex construction. Submersible Motor.

Submersible motors with 60hz frequency, 1180rpm speed, 6,6KV voltage, and 2000kW power rating. Complete with 50m power cable, and PT100 with 50m instrument cable. To be used as fire water pump drive units.

SME 36-inch, 2200kW, 6 Pole, 6600/3/60Hz, submersible motor. Super Duplex Construction. SME 36-inch, 2200kW, 6 Pole, 6600/3/60Hz submersible motors.

SME 36-inch, 1800kW, 4 Pole, 6600/3/60Hz Submersible Motor.

SME 36- inch, 1000kW, 8 Pole, 6600/3/60Hz, Submersible Motor

SME ROV24-6, 400kW, 6 Pole, 4100/3/30-64, SS316 Construction Motor, Double Ended to have Water Pump on one end and a Hydraulic Pump at the other end. Max Axial Thrust 100kN, Max Radial Thrust 40kN.

SME SS132-4, 5.5kW, 4 Pole, 400/3/50, SS316 Construction Subsea Motor for Thruster application (reversing Propeller mounted directly on shaft).

SME ROV16-2, 400kW, 2-Pole, 3300/3/60, SS316 Construction Subsea Motor with integral Thrust Bearing and Interface to suit operation with Water Pump (vertical operation).

SME ROV12-2, 48kW 65HP, 2-pole 3000/3/50, Aluminium Construction ROV Motor fitted with Rexroth A10VO28DFR1/31R-PSC62N00 Hydraulic Pump. Motor to have Burton Connector for Power Leads. Fitted with Temperature Sensing and Water Detectors terminated on Subconn or similar connector. Power Conductor and Sensor Connector Blocks to be in the same position on the motor at opposite ends (or as requested). Epoxy coated for protection. 4kw submersible motor, to be connected to a worm drive and gearbox. Supply voltage 440V, three phase. SME ROV10-4, 4kw, 4 Pole, 440V 50/60Hz, SS316 Construction Subsea Motor

SME ROV14-4 75Kw/100HP, 4-pole, 3000/3/60, anodised aluminium subsea motor. Double-ended motor with Interface to suit Sauer and Kawasaki Hydraulic Pumps.

300 kW electric motor, 1800 rpm, 4160V 60Hz, electric supply, with adaptation flange to fit with Sauer Danfoss hydraulic pump 90 R 250 type, standard splined shaft.

SME ROV14-4, 66kW/88HP, 4-pole, 3000/3/60, Anodised Aluminium Subsea Motor, with Interface to suit Hydraulic Pump. SME ROV10-2, 75HP, 2 – Pole, 3000/3/60, SS316 construction. Subsea Motor fitted with SMP 9WH-4 Stage NAB Construction Pump to provide 4000L/M at 5Bar or 1060GPM at 170ft Head. Motor is oil filled and externally compensated. Tube connection for Power and Subconn or equivalent connector for Water Detector and Temperature Monitoring. SME ROV22-14, 120HP, 14-Pole, 3000/3/60, SS316 construction. Subsea Motor fitted with Jetech 15055-UW-H Subsea Quintuplex High Pressure Pump to provide 50L/M at 850Bar. Motor is oil filled and externally compensated. Tube connection for Power and Subconn or equivalent connector for Water Detector and Temperature Monitoring. SME ROV22-12, 120HP, 12-Pole, 3000/3/60, SS316 construction. Subsea Motor fitted with Jetech 100J3-UW-H Subsea Triplex High Pressure Pump to provide 46L/M at 850Bar. Motor is oil filled and externally compensated. Tube connection for Power and Subconn or equivalent connector for Water Detector and Temperature Monitoring.

SME ROV18-4, 260kW, 350 HP, 4 Pole, 3000/3/60, Duplex Stainless Steel Construction Subsea Motor. To drive close coupled Hydraulic Pumps ( Bosch Rexroth Pump A11VLO-260, and Bosch Rexroth Pump A10VSO-4). SME ROV10-4, 40kW, 4 Pole, 3000/3/60, SS316 Construction Subsea Motor fitted with PTS Sterling 350C-1, 316SS Submersible pump to deliver 88 litres per second at 21 meters total developed head. Duty Power: 27.5 kW. Duty Thrust: 575 kg, NOL Power: 28.2 kW. Shut Head Thrust: 860kg. SME ROV10-2, 22kW, 2 Pole, 300/3/60 SS316 Construction Subsea Motors, fitted with PTS Sterling 200E-1, 316SS Submersible pumps to deliver 44 litres per second at 21 meters total developed head. Duty Power: 16.6 kW. Duty Thrust: 250 kg, NOL Power: 17.5 kW. Shut Head Thrust: 400 kg.

SME ROV12-8, 3HP, 8 Pole, 480v 23Hz, Aluminium Construction Subsea Motor.

SME ROV24-6, 400kW, 6-Pole, 4100/3/30-64, SS316 Construction Motor. Double Ended to have Water Pump at one end, and the Hydraulic Pump at the other end. SME SS132-4, 5.5kW, 4 Pole, 400/3/50, SS316 Construction Subsea Motor for Thruster application (reversing Propeller mounted directly on shaft). SME ROV10-4, 20HP, 4 Pole, 440/3/50-60, Aluminium Construction Subsea Motor to drive Hydraulic Pump. SME ROV14-2, 375kW, 2 Pole, 3300/3/60, SS316 Construction Subsea Motor to be fitted to your Water Pump. Flange and Shaft requirements to be advised by the client. SME ROV16-2, 400kW, 2 Pole, 3000/3/50, SS316 Construction Subsea Motor fitted to SME SS316 Construction/NAB Impeller Water Pump. Unit to be tested at rated performance in SME Test Facility. SME ROV10-4, 11.5kW, 4 Pole, 400/3/50, SS316 Construction Double Shafted Subsea Motor. To be a drop in replacement for the SubAtlantic Motor. SME ROV10-4, 2.2kW, 3HP, 4-Pole, 600/3/60, Aluminium Construction Subsea Motor complete with Flange and Shaft to interface with your Gearbox. Power Cables in Oily Tube. Motor to be epoxy coated for protection.

SME ROV10-4, 15kW 20HP, 4 Pole, 415/3/50, Aluminium Construction Subsea Motor, Coupled to Rexroth A10VSO28DFR Hydraulic Pump. Subconn Connectors for Power HPBH4F, and instrumentation MCBH4MAL (Capped). Epoxy coated for protection.

SME ROV14-4, 150kW, 4 Pole, 4160/3/60, SS316 Construction Subsea Motor. Fitted to SME SS316 Construction/NAB Impeller Trenching Water Pump to produce rated Pump performance. Motor fitted with Thermex/Fluidex Heat Changer, circulation Gear Pump, and Associated Plumbing. Horizontal or Vertical Operation. Unit to be tested at rated performance in SME Test Facility.

SME ROV24, 150kW 200HP, 3300/3/50. 12 Pole, 500rpm, SS316 Construction Subsea Motor to drive Dredge Pump.

SME ROV14-4, 50kW, 4 Pole, 400/3/50, SS316 Construction Oil filled Subsea Motor. Motor fitted with 3 x RTD's (1 x Redundant), 1 x Water Detector. Speed Monitoring in separate air filled chamber. Motor to be used with compensation circuit including gearbox. Motor to have shaft and flange as per customer requirements (female shaft possible). Motor suitable for vertical operation with no axial load exerted on the motor by the driven equipment.

SME ROV14-4, 100kW, 4 Pole, 400/3/50, SS316 Construction Oil filled Subsea Motor. Motor fitted with 3 x RTD's (1 x Redundant), 1 x Water Detector. Speed Monitoring in separate air filled chamber. Motor to be used with Compensation circuit including gearbox. Motor to have shaft and flange as per customer requirements (female shaft possible). Motor suitable for vertical operation with no axial load exerted on the motor by the driven equipment.

ROV14, 75HP / 55kW, 4 Pole, 1800rpm, 3000/3/60, Aluminium Construction Subsea Motor. Epoxy coated for protection. SS316 can also be offered. ROV14, 100HP / 75kW, 4 Pole, 1800rpm, 3000/3/60, Aluminium Construction Subsea Motor. Epoxy coated for protection. SME ROV14-2, 260kW, 2 Pole, 3000/3/60, Duplex St-St Construction Subsea Motor. Fitted to SME Duplex St-St Construction/NAB Impeller Trenching Water Pump, to produce Pump performance 1200m3/Hr at 6 Bar. Motor fitted with Thermex/Fluidex Heat Changer, Circulation Gear Pump and Associated Plumbing. Horizontal Operation. Unit to be tested at rated performance in SME Test Facility. Motor Oil/water filed, ambient pressure compensated. Depth rate 1500m. (2 off) Bearings PT sensors included. (2 off) Water ingress detectors included.

SME ROV22-8, 185kW, 250HP, 8 Pole, 230/3/60, SS316 Construction. Oil filled externally compensated Subsea Thruster Motor. SME ROV14-4, 250kw /335Hp, 4-Pole, SS316 Construction, 3300/3/50 Subsea Motor. To Interface with your A4VG250 Hydraulic Pumps.

SME ROV22-4, 150kw, 4 Pole, 6000/3/50, SS316 Construction Subsea Motor to Drive Hydraulic Pumps (Model TBA)

SME ROV14-4, 110kW 150HP, 4 Pole, 3300/3/50,60hz, Aluminium Construction Subsea Motor (epoxy coated for protection). Fitted with Rexroth A11VLO19DRS Hydraulic Pump to produce 240L/Min at 210 Bar.

SME ROV14-4, 75HP, 4 Pole, 3300 /3/60hz, Aluminium Construction Subsea Motor. SME ROV14-2, 260kW 350HP, 2 Pole, 4160/3/60, SS316 Construction Subsea Motor. Fitted to SME SS316 Construction/NAB Impeller Water Pump, to produce 500m3/hr at 16 Bar. Unit to be tested at rated performance in SME Test Facility. SME ROV14-2, 260kW 350hp, 2 pole, 4160/3/60, SS316 Stainless Steel Construction Motor to suit operation with Water Jetting Pump. Flange and Shaft requirements to be advised. SME ROV10-2, 18.5kW, 25HP, 2 Pole, 3000/3/50, Aluminium Construction Subsea motor to drive 6-inch Water pump. Epoxy coated for protection. SME ROV12-4, 56kW, 75HP, 4-Pole, 3000/3/60, Aluminium Construction Subsea Motor to direct couple Hydraulic Pumps to both ends. SME ROV10-2, 3.5kW, 2-Pole, 1000-3000V (customer to choose), 60Hz, SS316 Construction Subsea Motor. Seaconn Power Connector.

SME ROV12-4, 100HP, 3000/3/60, Aluminium Construction Subsea Motor to exactly match Curvetech Motor. SME ROV10-2, 15kW 20HP, 2 Pole, 3000/3/60, Aluminium Construction Subsea Motor. Coupled to Rexroth A10VSO10DFR1/52R-PUC64N00 Hydraulic Pump to provide 30L/min at 210 Bar. Motor fitted with Temperature and Water Detectors, terminated in Subconn MCBH4M Connector. Power supplied through Oily Tube. ROV Motor 200kW 335HP, 4 Pole, 1800rpm, 4160/3/60, SME ROV14, SS316 Construction Subsea Motor to drive hydraulic pump.

ROV Motor 100kW 150HP, 2 Pole, 4160/3/60, SME ROV14-2, SS316 Construction Motor to suit operation with water jetting pump. Flange and shaft requirements to be advised.

ROV Motor 150kW, 4 Pole, 1800 rpm, 4160/3/60, SME ROV14, SS316 Construction Subsea Motor to drive hydraulic pump.

SME 14 inch, 150HP, 8 Pole, 380vac/3ph/50hz, SS316 Construction. This is an Inverted Submersible Motor to drive a Propeller Pump. SME 26 inch, 350kW, 8 Pole, Super Duplex Construction Submersible Motor to drive Turbine Pump. SME ROV14-2,135kW, 2 Pole, 3300/3/60, SS316 Construction Subsea Motor. Driving SME SS316 Construction Subsea Pump with NAB Impeller. To operate at 5 Bar. SME ROV 14-2, 260kW, 2 Pole, 3000/3/50, SS316 Construction Subsea Motor fitted to SME SS316 Construction/NAB Impeller Water Pump to Pump performance between and 1000m3/hr at 40M.SME ROV14-4, 150kW 200HP, 4 Pole, 4160/3/60, SS316 Construction Subsea motors. To drive Centrifugal Pump through close coupled arrangement with Coupling housing. Motor to have Power terminated through 15m of 32mm Oily tube. Temperature and Water Connectors terminated in Burton 5506-1508-0002 connector. ROV 15KW HPU. SME ROV10-2, 15kW 20HP, 2 Pole, 3000/3/60, Aluminium Construction Subsea Motor. Coupled to Rexroth A10VSO10DFR1/52R-PUC64N00 Hydraulic Pump to provide 30L/min at 210 Bar. Motor fitted with Temperature and Water Detectors terminated in Subconn MCBH4M Connector. Power supplied through Oily Tube. 3000msw depth rated.

SME ROV10-2, 18.5kW, 25HP, 2 Pole, 3000/3/50, Aluminium Construction Subsea motor to drive 6-inch Water pump. Epoxy coated for protection.

SME ROV12-4, 56kW, 75HP, 4-Pole, 3000/3/60, Aluminium Construction Subsea Motor to direct couple Hydraulic Pumps to both ends. SME 10-inch, 37kW 50HP, 2 Pole, 380/3/50, Ni Al Br Construction Submersible Motor, with Modified Shaft and Flange to suit drawing for Hayward Tyler MS 201-50 motor, and existing pump model 7F23. Fitted with 30m 25mm2 Mulitcore power cable internally spliced in the motor. SME ROV14-2, 260kW, 2 Pole, 3000/3/60, Duplex St-St Construction Subsea Motor. Fitted to SME Duplex St-St Construction/NAB Impeller Trenching Water Pump, to produce Pump performance 1200m3/Hr at 6 Bar. Motor fitted with Thermex/Fluidex Heat Changer, Circulation Gear Pump and Associated Plumbing. Horizontal Operation. Unit to be tested at rated performance in SME Test Facility. Motor Oil/water filed, ambient pressure compensated. Depth rate 1500m. SME ROV14-4, 200kW, 4 Pole, 1800rpm, 3000/3/60 Anodised Aluminium Construction Subsea Motors to drive Parker Hydraulic Pumps. Motor with 5m of Oily Tube and cable. Motor fitted with PT100 and Water Detector terminated in Subconn Connector.

SME WATER JETTING PUMP for ROV TRENCHERS. SME now offers high quality, robust and reliable, water jetting pumps complete with SME submersible motor for all subsea operations. Ideal for ROVs, Trenchers, Dredgers and other underwater applications. Silvercrest/SME supply our own Pump/Motor combination. We offer a 2- pole, or 4-pole motor, coupled to our own designed pump (especially designed for trenching applications). Depth rating is 3000msw plus. The pump and motor combination is rigorously tested in our factory to full performance before despatch.

For example: SME ROV14-4, 185kW / 250Hp, 4 Pole, 4160/3/60, SS316 Construction Subsea Motor. Fitted to SME SS316 Construction/NAB Impeller Water Pump to produce 390m3/hr at 16 Bar. The SME Jetting Pump can also be offered complete with a 265kW, 2- Pole, 3300V 60Hz, 3500rpm, all 316 Stainless Steel motor. The Pump is single stage with the impeller mounted directly onto the motor shaft (So no pump bearings to wear). This Impeller is easily removed and replaced as the only wear point. This pump provides flow rates from 1000-1500m3/h.

SILVERCREST / SME. TEL: (+44) 1285 760620 EMAIL: Sales@SilvercrestSubmarines.com

Some recent submersible subsea and ROV motor and HPU projects for our subsea clients, have included the following: Our motors are manufactured to the clients exact requirements as indicated in the final specification, and the SME drawings.

a) Submersible motors each 550Hp, 50Hz, 2-poles (2900rpm), at 6000v. This being for a major project, that will couple Kazis pumps (turbine type suitable to enter Bore holes) with Silvercrest / Submersible Motor Engineering motors. All motors to have NEMA flange to connect with the pumps. Installation depth expected to be 350m.

b) SME 10-inch, 180kW 240HP, 2-Pole, 3600rpm, 480/3/60, SS316 construction Submersible Motor. c/w Inbuilt Heat Exchanger for High Ambient Temperature. Motor is Water Filled and Water Cooled.

c) SME 12 inch, 250kW 335HP, 2 Pole, 3600rpm, 1000/3/60, SS316 Construction Submersible Motor. c/w Inbuilt Heat Exchanger for High Ambient Temperature. Motor is Water Filled and Water Cooled. d) SME ROV14, 150Kw, 4 Pole, 3000/3/50, 1490rpm Stainless Steel Construction Subsea Motor designed to close couple to Rexroth A11VLO190DRS-11-LN-12N00 Hydraulic Pump. The motor will cool itself in the ambient seawater. Sensors and electrical connector are included in the motor price. e) Two new submersible motors fitted with jetting pumps for a subsea trencher. SME ROV14-2, 150kw, 2-Pole, 3000/3/60, SS316 Construction Subsea Motor fitted with 250GM-4C-177-3550 Nickel Aluminium Bronze Pump to produce 210m3/Hr (two pumps 420m3/h). Absorbed Power 130kW with 151kW Non Overloading. f) ROV54, Power: 1 HP. Operating Depth: 2000 meters, 440AC/3 Phase, 60Hz, and a speed of 3500 RPM. The motor to drive a submersible seawater centrifugal pump mounted onto the motor shaft. The shaft will be fully supported on both sides. The pump does not give pressure, just flow. SME ROV5-4, 1HP, 4Pole, 440/3/60, SS316 Construction Motor, to drive Water Pump.

g) Submersible electric motor with the shaft and flange modified to meet the clients exact technical requirements. SME ROV10-6, 7kW, 6-Pole, 440/3/50, 1000rpm, Duplex Construction. Externally Compensated Subsea Motor to close couple to Worm Gearbox 30-40:1 suitable for operation during 30G Vibration.

h) SME ROV8-4, 5HP, 4 Pole, 240/3/60, Aluminium Construction Subsea Motor to Close couple to your Hydraulic Pump.

k) Water Filled Submersible motor for operation in a shaft containing potable water. Motor to be suitable for 220 kW at 1485 rpm on 400 volt, 3 Ph 50 Hz supply. Maximum Water temperature 15 deg C. SME 14-INCH, 300HP 220Kw, 4- Pole, 400/3/50 SS316 Construction Submersible Motor. Flange and Shaft requirements as per the clients specification.

l) SME ROV14-2, 90kw, 2 Pole, 3000/3/60 SS316 Construction Submersible Oil Filled Motor coupled to Hydroflo Pump Model 9HH-2 stage Water Pump to Provide 5000 L/m at 7 Bar. Pump Discharge size advised by the Client.

m) SME ROV16-2, 400kW, 2-Pole, 3300/3/60, SS316 Construction Subsea Motor with integral Thrust Bearing and Interface to suit operation with Water Pump (vertical operation).

n) 15kw submersible motor, submerged up to 10m (to drive a hydraulic pump). 400vac, 3 phase, 50Hz. Speed 1465rpm. Motor to be placed in a hydraulic reservoir, or clean water pod (client to select). Motor to be oil free. Stainless steel construction. SME ROV10-4, 15kw, 4 Pole, 400/3/50, SS316 Construction Subsea Motor (Air Filled).

o) Three 200Kw motors, 4000v, 60hz, 1800RPM, Anodised aluminium construction, to be fitted to a new underwater excavator. To be mounted with hydraulic pumps. ROV14, 200kW, 4-Pole, 1800rpm, 4000/3/60, Anodised Aluminium Construction Subsea Motor to Drive Hydraulic Pump. Interface to suit Hydraulic Pump. Flange and Shaft as required by client. p) Replacement 20HP, 880v, 60Hz, 3 phase, submersible motor for a hydraulic power pack. Foot mountings are adjustable. SME.ROV6-20 submersible motor.

q) Three submersible motors for 200m water depth, rated for VSD. To operate pumps that will rotate between 300 and 600 rpm. The gearbox having a reduction of 3.5. Motor speed has to be within +/- 1000 and 2000 rpm.

r) ROV14, 75HP / 55kW, 4 Pole, 1800rpm, 3000/3/60, Aluminium Construction Subsea Motor. Epoxy coated for protection or SS316.

s) ROV14, 100HP / 75kW, 4 Pole, 1800rpm, 3000/3/60, Aluminium Construction Subsea Motor. Epoxy coated for protection.

t) Two Parker F11-150 hydromotors mounted on gearbox. Max rotations per motor: 2467 rpm. Max. torque per motor: 484 Nm. Most used case: Max rotations per motor: 1337 rpm. Max torque per motor: 131 Nm. We suggest our ROV144-130kW (175Hp), 4P, 3300V, 82Hz, 2500 RPM, motor. At the slower speeds the performance will match the requirements of roughly: 25kW, 1811 Volts, 45Hz, for the 130kW motor. It is understood that these motors will be running on a VVVF Drive, and that the Drive Output Voltage will be roughly proportional to the Hz. Motors are externally compensated so depth can be as much as 3000m. u) Three Parker F11-250 hydromotors mounted on a gearbox Max rotations per motor: 2230 rpm. Max. torque per motor: 864 Nm. Most used case: Max rotations per motor: 1141 rpm. Max torque per motor: 278 Nm. We suggest our ROV164-210kW (280Hp), 4P, 3300V, 74Hz, 2250 RPM motor. At the slower speeds the performance will match the requirements of roughly: 40kW, 1688 Volts, 38Hz, for the 210kW motor. It is understood that these motors will be running on a VVVF Drive and that the Drive Output Voltage will be roughly proportional to the Hz.

v) A submersible motor for use on a ROV with a depth rating of maximum 50 meters in seawater. Double shaft motor 56 kW, 3000V, 3-phase 60Hz, 1800 rpm. On each side of the motor a pump unit will be fitted. SME ROV12-4, 56kW, 75HP, 4-Pole, 3000/3/60, Aluminium Construction Subsea Motor to direct couple Hydraulic Pumps to both ends. This will be a motor with Female Shaft, and close couple the pump to the motors using a face seal against the pump.

x) A 3300vac, 100HP, submersible motor, 3phase, 60hz. 1750RPM. To be used to drive a hydraulic pump. Standard shaft size and flange for a 40gpm pump. ROV14-4, 100HP, 4-Pole, 3300/3/60, Aluminium Construction, Subsea Motor to drive Hydraulic Pump. Flange and Female Shaft to suit your Pump. Can be offered in SS316 Construction if required, instead of Aluminium.

y) Submersible motors to match with Rexroth hydraulic pumps. 30Kw, 4P, 380V / 50HZ submersible motor to match with 4VSO40DR/32R-PPA Rexroth pump. Oil temperature at 0-80 degrees. Horizontal mounting, with hollow shaft. The motors to be contained in a Hydraulic oil bath. 45kw submersible motor to match with A4VSO71DR/32R-PPA Rexroth pump. 75kw submersible motor to match with A4VSO180DR/32R-PPA Rexroth pump. SME ROV10-4, 30kW, 4 Pole, 380/3/50, SS316 Construction Submersible Motor to direct Couple to A4VS040 Hydraulic Pump. SME ROV10-4, 45kW, 4 Pole, 380/3/50, SS316 Construction Submersible Motor to direct Couple to A4VS071 Hydraulic Pump. SME ROV14-4, 75kW 4 Pole 380/3/50 SS316 Construction Submersible Motor to direct Couple to A4VS0180 Hydraulic Pump.

z) An electric submersible motor to power a submersible ROV TMS. Power 17.5kw, Speed 1800rpm, and Voltage 3000v at 60hz. To be mated with a hydraulic pump ( Parker PV016 R1K1T1N MMC piston pump). SME ROV10-4, 17.5kW, 4 Pole, 1800rpm, 3000/3/60, Aluminium Construction Subsea Motor to drive Parker Hydraulic Pump. SS316 motor construction also available.

a1) The rewire and service of two 150hp, 1750rpm, 3000/3/60, Curvetech motors. We are able to offer a Full Factory Rewind and service of Curvetech 150hp motors. Our standard refurbishment programme includes the following:

Any further work deemed necessary as a result of the factory inspection will be quoted separately, and a decision given by the customer as to the course of action required on an item-to-item basis.

Submersible motors to match with Rexroth hydraulic pumps. 30Kw, 4P, 380V / 50HZ submersible motor to match with 4VSO40DR/32R-PPA Rexroth pump. Oil temperature at 0-80 degrees. Horizontal mounting, with hollow shaft. The motor to be contained in a Hydraulic oil bath. We are pleased to offer a highly modified Cast Iron Motor (30kw, 4-pole, 380/3/50, suitable for running immersed in an oil bath, with a special Flange and Female Shaft to accept the Rexroth hydraulic Pump.

Subsea motor 300kW, 3.3kV, Double Ended Drive for Hydraulic Power. SME ROV18-4, 300kw, 4 Pole, 3300/3/60, SS316 Construction Subsea Motor.

A submersible electric motor to drive a dredging pump, in a water depth of 20m. SME ROV18-4 ,400kW 530HP, 4 Pole, 400/3/50, SS316 Construction, Subsea Motor with 20m of Cable terminated in Bulkhead on the motor. Motor with RTD's and Water Detector.

ROV Motors.

4) HPU for your underwater subsea project. SME ROV14-4, 185kW 200HP, 4 Pole, 3000/3/60, Aluminium Construction Subsea Motor coupled with Rexroth A11VL0190 Hydraulic Pump to deliver 285 LPM at 310 Bar. 5) High voltage motor-pump sets that will power-up the hydraulic power unit on an ROV. The requirements being 3000VAC 50Hz, 15kW, 1500rpm (motor), 20 Lpm (hydraulic fluid flow rate), 21 Mpa (pump outlet pressure). Two units for 1000msw and one unit for 1500msw. SME ROV10-4, 15kW 20HP, 4 Pole, 3000/3/50, Aluminium Construction Subsea Motor, Coupled to Rexroth A10VSO18DFR Hydraulic Pump to give 20L/m at 21 Mpa. Epoxy coated for protection.

Submersible motor for operations at 6000m. SME 145kw 8 Pole 1500rpm 6600/3/50 Submersible Motor. SME 400kw 4 Pole 1500rpm 6600/3/50 Submersible Motor.

We can offer our SME ROV22-12, 150kW, 12-Pole, 500rpm, 3300/3/50, SS316 Construction Subsea Motor. This motor will be manufactured to your exact requirements, and to interface with your submersible pump. SME ROV14-2, 186kW 250HP, 2-Pole, 3300/3/50, SS316 Construction Subsea Motor, with Flange and shaft to interface with Water Pump.

SME 400kw 4-Pole 1500rpm 3300/3/50 Submersible Motor.

SME 400kw 4 Pole 1500rpm 6600/3/50 Submersible Motor.

SME 145kw 8 Pole 1500rpm 3300/3/50 Submersible Motor.

SME 145kw 8 Pole 1500rpm 6600/3/50 Submersible Motor. SME ROV18-4, 300kW, 4 Pole, 1800rpm, 3000/3/60, SS316 Construction Subsea Motor to drive Hydraulic Pump.

SME ROV10-4, 40kW, 4 Pole, 1800rpm, 3000/3/60, SS316 Construction Subsea Motor to drive Hydraulic Pump. SME 10-inch, 37kW 50HP, 2 Pole, 380/3/50, Ni Al Br Construction Submersible Motor, with Modified Shaft and Flange to replace a Hayward Tyler MS 201-50 Motor and pump. SME 10-inch, 37kW 50HP, 2 Pole, 380/3/50, Super Duplex Construction Submersible Motor with Modified Shaft and Flange to replace a Hayward Tyler MS 201-50 Motor and pump. SME ROV14, 250kW, 4 Pole, 3000/3/50, SS316 Construction Subsea Motor fitted with A4VG250EP4D1/32R-NSD10F001DP Hydraulic Pump. SME ROV14, 250kW, 2 Pole, 3000/3/50, SS316 Construction Subsea Motor to Drive Water Pump. SME ROV14-4, 60kW, 4 Pole, 3000/3/50, SS316 Construction Subsea Motor fitted with A4VG40EP4D1/32R-NSC02F013DP and A10VO28DFR/31R-PSC62K01 Hydraulic Pumps at either end. SME ROV14-4, 150kW 200HP, 690/3/60, Anodised Aluminium Construction Subsea Electric Motor. Fitted with a Rexroth A11VLO260LRDS/11R-NTD12N00 (CW ROTATION) PUMP-PISTON-VARIABLE at one end, and a Rexroth AZPW-2x-019-022LRRXXMB-SO593P (CCW ROTATION) PUMP-SINGLE-GEAR-SAE`A` 19cc, at the other end. Motor will have Oily tube for Power, and Subsea Connector for Temperature and Water Ingress Sensors. Motor available in SS316 stainless steel if preferred.

Motor Rewinds and Refurbishment. Our standard motor refurbishment and rewind programme includes the following:

SILVERCREST / SME manufacture Submersible, ROV, Subsea electric motors to your exact technical specification. We also offer complete submersible electric motor rewinds, rebuilding, electrical conversion, and construction modification.

SILVERCREST / SME can repair, rewind, and completely rebuild the following listed motors. Alstra, Aturia, Bamsa, B. J., Elmaksan, Exodyne/EEMI, G.E., Hayward Tyler, Hitachi, Mercury, Oddesse, Pleuger, Saer, S.M.E., Subteck, Sumo, Sun Star, U.S.

6.6Kv Motors Available.

SILVERCREST / SME Email: sales@SilvercrestSubmarines.com

Silvercrest/ Submersible Motor Engineering 6600vac Subsea Motors.

SME 145kw 8 Pole 1500rpm 6600/3/50 Submersible Motor. SME 400kw 4 Pole 1500rpm 6600/3/50 Submersible Motor. SME ROV22-4 300kW 4 Pole SS316 Construction 6600/3/60 Subsea Motor to drive Hydraulic Pump. SME 36inch, 2200kW, 6 Pole, 6600/3/60Hz submersible motors

SME 36 inch, 1800kW, 4 Pole, 6600/3/60Hz Submersible Motor

SME 36 inch, 1000kW, 8 Pole, 6600/3/60Hz, Submersible Motor

SME 300Kw, 6600vac, 4-pole Subsea Motor.

SME 400Kw, 6600vac, 4-Pole HPU Subsea Motor.

We have manufactured many 6.6kV motors, mainly Submersible Pump Motors for various Mining, and Offshore applications. Usually we supply to Pump Manufacturers who fit these motors to their pumps.

We can offer the following high voltage motors, subject to agreed technical drawings: SME 36-inch, 550kW -540HP, 4 Pole, 10000/3/50, Super Duplex Construction Submersible Motor.

SME ROV22-4 300kW 4 Pole SS316 Construction 4500/3/60 Subsea Motor to drive Hydraulic Pump.

The method of construction changes at 4100V from Random Wound to Formed Coils so there is a jump from 4100V to the 4500V motor. The 4500V motor is constructed very similarly to the 6600V Motor. Silvercrest will bespoke manufacture virtually any shape and size of submersible motor and submersible pump required for subsea operations. We can offer a wide range of HPU and motor-pump sets complete, subject to any modifications, and changes you may require. For example:

SME ROV12-2 48kW 65HP 2-pole 3000/3/50 Aluminium Construction ROV Motor fitted with Rexroth A10VO28DFR1/31R-PSC62N00 Hydraulic Pump. Motor to have Oily Tube connection for Power Leads. Fitted with Temperature Sensing and Water Detectors terminated on Subconn or similar connector. Epoxy coated for protection. SME ROV14, 200kW, 268HP, 4 Pole, 3000/3/50, 1490rpm Stainless Steel Construction Subsea Motor designed to close couple to Rexroth A11VLO190DRS-11-LN-12N00 Hydraulic Pump. SME ROV10-4, 50HP, 4-Pole, 1000-3000/3/50 Anodised Aluminium Construction Subsea Motor. Fitted with Rexroth A10VO45DFR1/3xR-PSC62N00 Hydraulic Pump to provide 66L/m at 200 Bar. Motor fitted with Oily Tube connection for Power and Earth. Temperature and Water Detectors terminated in Subconn Connector. Hydraulic pump close coupled to Motor. SME ROV14-2 motor, 265kw 2-pole 3000/3/60 with Stainless Steel Construction. Fitted with a PTS Sterling 350D-1 ZFB Pump (wet end only). Operating at 2- pole, 60 hertz. Thrust developed at duty: 1820kg. Thrust at Shut-off: 3016kg. Approx. length of pump: 750mm. Bowl diameter: 340mm. SME ROV14-2 300kw 2 pole 3000/3/60 Oil filled Stainless Steel Motor with In built Circulation System and Heat Exchanger coupled to a Sterling 300M-3 Zinc Free Bronze Pump with a duty of 828cu.m/hr at 9 Bar. ROV20-4 type motors, 4 pole/6600vac/3 phase/60hz, with stainless steel construction. Double Ended for fitment with Sauer hydraulic pumps Series-90, with Subsea Connectors for Power and Sensors. We can offer the ROV20 motor with shafts at both ends, to mate with the Sauer Series 90 pumps . SME ROV24-6, 400kW, 6-Pole, 4100/3/30-64, SS316 Construction Motor. Double Ended to have Water Pump at one end, and the Hydraulic Pump at the other end. SME ROV228, 325kW, 8-pole, 3300/3/60, SS316 construction, Subsea Motor to drive Water Pump. SME 36-inch 2200kW 6-Pole 6600/3/60Hz Super Duplex construction. Submersible Motor manufactured for a shaft down application. Motor fitted with 4 x PT100 (3 internally in the windings, 1 on the thrust bearing ). Suitable for connection to CD pump. SME 36-inch, 550kW -540HP, 4 Pole, 10000/3/50, Submersible Motor, Super Duplex Construction.

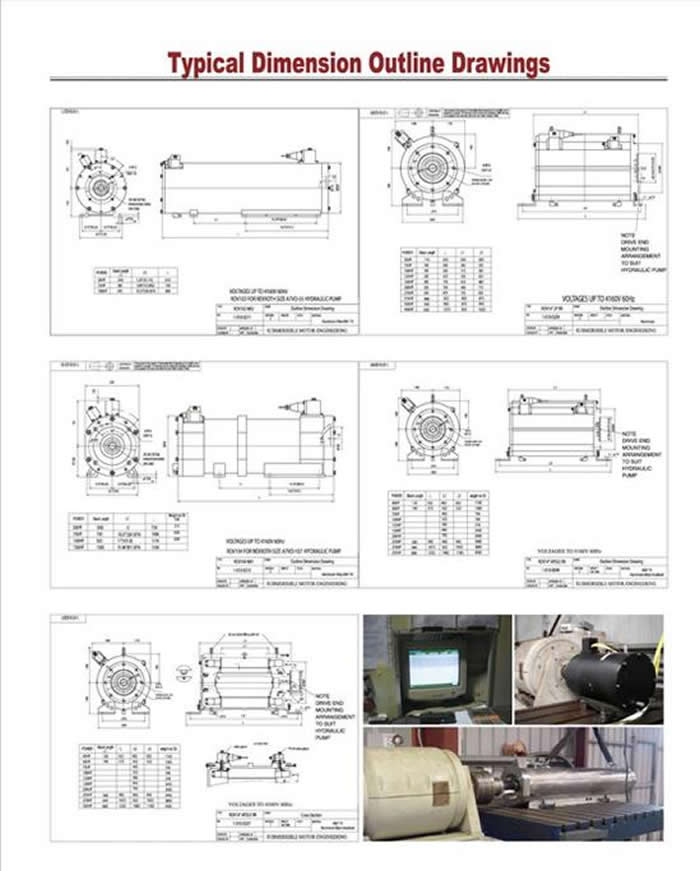

SPECIFICATIONS FOR SME SUBSEA ELECTRIC MOTORS.

SILVERCREST / SME MOTORS FOR OUR SUBSEA CLIENTS.

ROV submersible motors. We are pleased to be able to offer a replacement motor to meet your specific requirements. Volts 3000VAC Poles 2 Speed 3450 RPM Full Load Torque 769Nm Start Torque 1187Nm Depth Rating 3000 Mts Compensation Oil filled - external compensator (not included) Housing 316 Stainless Steel Mounting Vertical Shaft Spec to be advised KW 290kW @60 Hz HP 390HP @ 60Hz Weight 404kG max Length 1000mm max

EXAMPLES OF OTHER SUBMERSIBLE AND SUBSEA MOTORS WE HAVE MANUFACTURED.

SME 36-inch, 550kW -540HP, 4 Pole, 10000/3/50, Super Duplex Construction Submersible Motor.

SME 36inch, 2200kW, 6 Pole, 6600/3/60Hz submersible motors

SME 36 inch, 1800kW, 4 Pole, 6600/3/60Hz Submersible Motor

SME 36 inch, 1000kW, 8 Pole, 6600/3/60Hz, Submersible Motor

55HP hydraulic power pack motors.

ROV 14-55HP, 3000V, 60Hz, 4 Pole Motor (with pump attached).

Final dimensions and shaft arrangement to be confirmed by customer, foot mountings are adjustable and can be manufactured to suit customer requirement. Volts 3300VAC / 60hz / Three Phase Poles 4 Speed 1750 RPM Depth Rating 3000 Meters nominal Compensation Oil filled - external compensator Housing 316 SS or Hard Anodized Aluminium. Mounting Horizontal Shaft TBC KW 41kW @ 60 Hz Insulation Rating >16kV @ 140 deg C (Mylar) Shaft Seals Bergman mechanical seals.